04 – A TRIBUTE TO A GOOD FRIEND

Ano 09 (2022) – Special Issue on Herbert Artigos

![]() 10.31419/ISSN.2594-942X.v92022iSpeciala4UK

10.31419/ISSN.2594-942X.v92022iSpeciala4UK

Uwe König, uwe.konig@panalytical.com

ABSTRACT

Do you have a special friend that you could trust with your life? One that no matter the mistakes you make or have made, you’ll never be judged. I have had that privilege and lost him in May 2022. Prof. Dr. Dr. Herbert Pöllmann was a passionate researcher, university teacher and loyal friend that always had time and open ears for his friends, students, and colleagues. Herbert accompanied me for 28 years and I can truly say he shaped me and my life.

TIME AS STUDENT

After starting 1994 as geology student at the Martin-Luther-University in Halle (Germany) it took not long to get my first student job at the mineralogy department. At this time, I experienced Herbert as a demanding professor that expected a lot but at the same time gave many things back such as knowledge, experience and motivation. So it happened that after being a student for only 2 years I could already put my name 1996 on my first publication together with Herbert and other researchers about microscopy and quantitative X-ray diffraction (XRD) using the Rietveld method (Motzet et al.,1997; Rietveld, 1969); Pöllmann et al., 1997).

This work gave the idea for my diploma thesis. Herbert wanted to bring the Rietveld method to the mining industry and therefore we started to work on phase quantification of iron ores (König et al., 2002: König, 2000; König and Pöllmann, 2000).

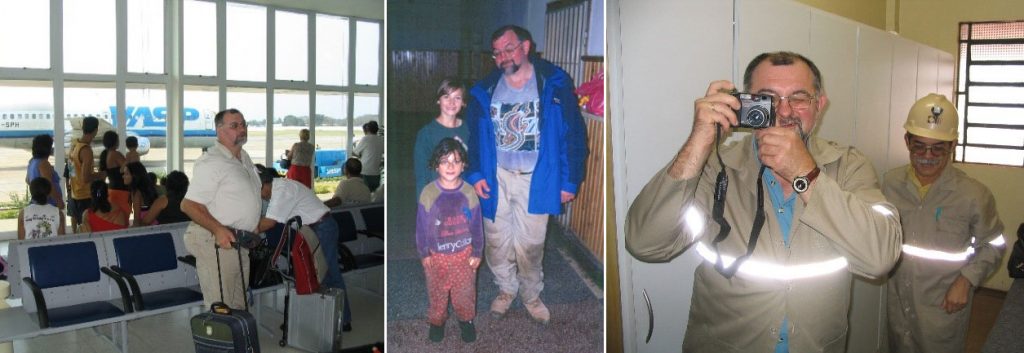

Just before finishing the work in 2000 Herbert arranged as part of a student exchange program a trip to Brazil to the UFPA, Universidade Federal do Pará, in Belém (Brazil) which was the begin of many long-lasting friendships, research visits and clearly also my empathy for the country Brazil – it’s culture, nature and people (figure 1 and 2).

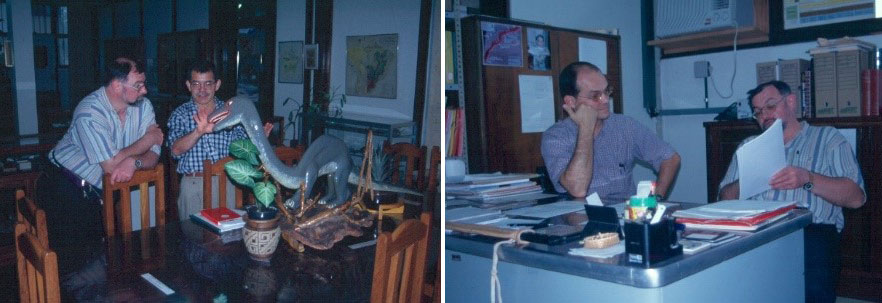

Figure 1 – Herbert at the X-ray laboratory of the UFPA (Belém) together with Prof. Dr. Marcondes Lima da Costa and Prof. Dr. Rômulo Simões Angélica

Figure 2 – Left – Herbert together with Prof. Dr. Thomas Scheller at the X-ray laboratory of the UFPA (Belém), Right – Herbert at the 31st International Geological Congress in Rio de Janeiro with Prof. Dr. Lília Mascarenhas Sant’Agostino and Dr. Luciano Gobbo.

TRAVELS TO BRAZIL

What started in 2000 with the first visit to Belém, Pará (Brazil) continued in almost yearly travels to Brazil, together with Herbert and later in my new role at Malvern Panalytical.

After first field trips with Herbert in the near Belem region such as to the Ilha de Mosqueiro together with Prof. Marcondes Lima da Costa (figure 3), to study the costal laterite horizons or to Barcarena together with Prof. Rômulo Simões Angélica, to the bauxite and aluminium processing plant – Herbert brought me to several other parts of the country. Only some of the field trips in Brazil that I will always remember are:

- the Carajás Mine, the largest iron ore mine in the world, located in the municipality of Parauapebas, state of Pará in the Carajás Mountains of Northern Brazil. The mine is operated as an open-pit mine, and is estimated to contain roughly 7.2 billion metric tonnes of iron ore (plus gold, manganese, bauxite, copper, and nickel) – Herbert and myself collects samples for my Diploma thesis.

- the Azul mine, also located in the Caracas mining district, representing one of the largest manganese reserves in Brazil, having estimated reserves of 64.2 million tonnes of manganese ore grading 28% manganese metal – together we collected samples for various industrial research projects to use manganese in cementitious products (figure 4).

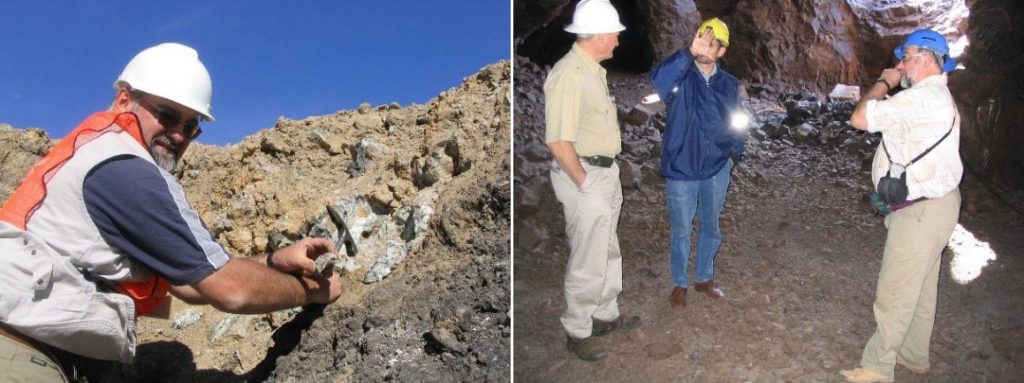

Figure 4 – Herbert during the field trip to the Azul mine (manganese) within the Carajás mining district.

- the Igarapé Bahia deposit, also located in the Carajás mining district, with estimated reserves of 219 Mt @ 1.4% Cu and 0.86 g/t Au (Tallarico et al.,2005). The mine operation started in 1990, producing 3119 oz of supergene gold until its closure in 2002. During the mine visit we were looking for secondary minerals, such as phosphates, hydroxides and oxides containing Cu, Mn, Fe and other elements.

- the Urucum mine, an underground manganese mine with an on-site beneficiation plant which is located at State of Mato Grosso do Sul in Brazil, extracting high and medium grade manganese oxide ores with an average content of 46% manganese grade. We collected several residues from the manganese mining and processing.

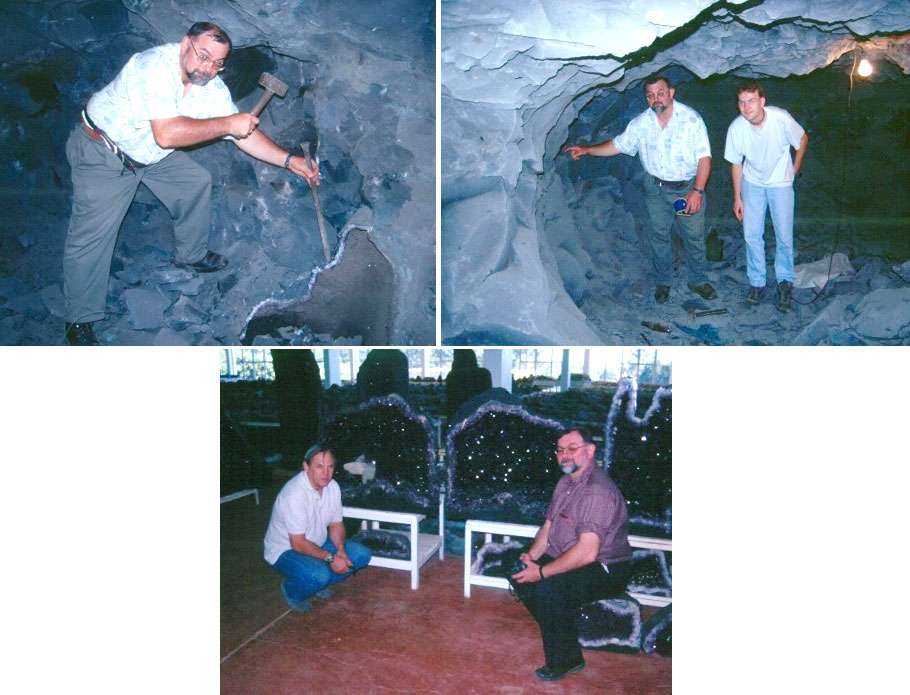

- Ametista do Sul amethyst mines, which are in the northern part of the state of Rio Grande do Sul in southwestern Brazil. This is the main area that produces Brazil’s famous amethyst geodes. Production is about 400 tonnes per month. These geodes occur in basaltic volcanic flows formed about 130 million years ago. As Herbert and myself are passionate mineral collectors the visits to Ametista do Sul, especially the visits together with Prof. Dr. Reinhard Wegner, were always a highlight. Not only seeing how the geodes are excavated in the mines, but also the shops – huge as a football stadium – selling the amethyst and many other minerals to all parts of the world, are unforgettable memories (figure 5).

Besides countless scientific publications about the research in Brazil, Herbert also published many of his experiences in the German magazine “Der Aufschluss” – a bimonthly magazine for mineral collectors and anybody that is interested in mineralogy, geology and palaeontology, VFMG (Vereinigung der Freunde der Mineralogie und Geologie). I had the chance to have Herbert a co-author for two articles about Brazil (König and Pöllmann, 2002; 2008).

FIELD TRIPS AROUND THE WORD

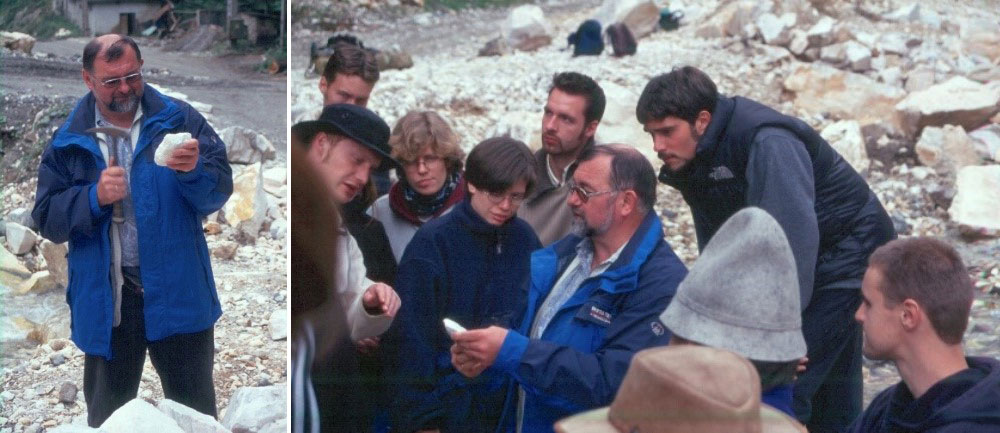

Various field trips with students or research partners brought us also many other parts of the world. Unforgettable are the various trips to South Africa’s mineral deposits together with Prof. Dr. Johan de Villiers (figure 5), and the excursions to Romania together with Prof. Dr. Marcel Benea (figure 6) (König et al., 2001).

FROM A SUPERVISOR TO THE “DOKTORVATER”

During the last 4.5 years at the university as PhD student Herbert passed on all his life experience to me to get me ready for the work in industrial environments. The German word “Doktorvater” brings it to the point, figure 8. Besides scientific research Herbert passed on his experience how to deal with students and industrial partners, how to present in foreign languages in-front of a big audience, or how to handle travelling to remote areas of the planet.

Figure 8 – Prof. Dr. Richard Wenda and Herbert at the mineralogical institute in Halle (Germany), my two “Doktorväter” and supervisors for the PhD thesis

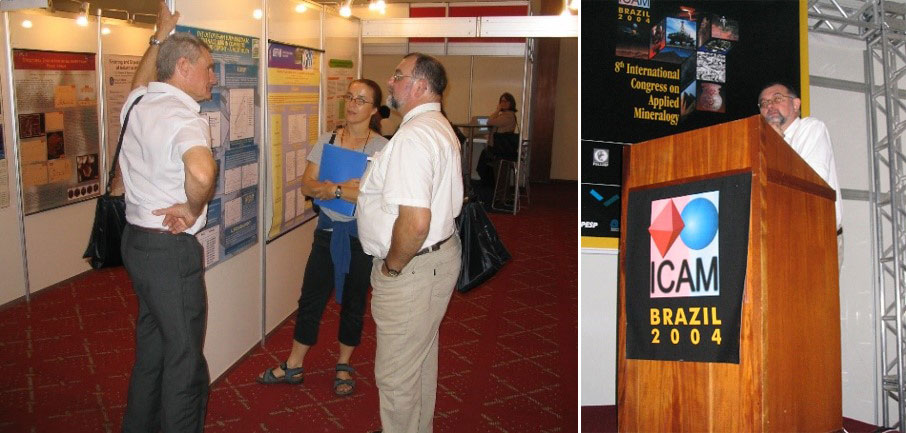

2004 we travelled together to the 8th ICAM conference in Águas de Lindoia, Brazil to present first results of my PhD work on manganous layered double hydroxides (LDHs) (König, 2007). It was there where Herbert arranged the contact to my future employer Panalytical (now Malvern Panalytical) (figure 9).

Figure 9 – 8th ICAM conference in Águas de Lindoia, Brazil, Herbert with Dr. Sabine Verryn and Prof. Dr. Johan de Villiers (both from the university Pretoria, South Africa)

A FRIEND AND TUTOR FOREVER

While he is no longer with us, Herbert’s legacy lives on – not only with his students or „kids“(as he always called us) but also with several of which are or were employed in the industry or research institutes to whom he always maintained connection.

In addition of a friend and tutor, Herbert became a customer of myself working at Malvern Panalytical were also his PhD students Luciano Gobbo, Leonardo Negrão and former co-worker Thomas Witzke found a fulfilling position as application specialists for X-ray diffraction.

Together we initiated numerous events such as the BMA (Building Material Analysis) workshops organised in Halle (Germany) from 2005 to 2015 with the idea to bring scientists from research institutes, industries and suppliers of analytical equipment together to discuss the latest trends and innovations in the industry. Highlight was the participation of Dr. Hugo Rietveld – the developer of the Rietveld method for phase quantification using XRD (Rietveld, 1969) (figure 10).

Figure 10 – Unforgettable meeting with Dr. Hugo Rietveld during one of our BMA workshops in Halle (Germany)

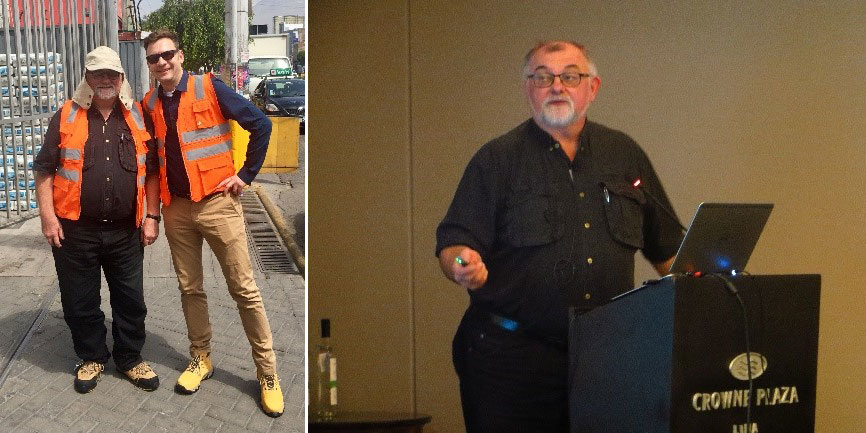

Later I had the chance to adapt the idea of the workshop towards the mining industry and started the OMA (Ore and Mineral Analysis) workshops in 2015. In October 2022 the 34th edition was held in Quebec, Canada. Wherever possible, Herbert supported and contributed to the events with presentations and discussions like in Lima (Peru) – a hotspot for copper mining in South America (figure 11).

LAST PROJECT – SPECIAL ISSUE MINERALS

Besides the mission to create new raw materials from industrial residues, Herbert‘s aim was to bring mineralogical knowledge into industrial processes to make manufacturing of cement and metals more efficient and sustainable. Nowadays mineralogical monitoring is a standard tool during cement production, thanks also to Herbert’s research and studies. The mining and minerals industry just started to implement such new technologies. Therefore, in 2020 just after the global pandemic hit the world, we decided to publish a Special Issue of MINERLAS to demonstrate the “Value of Mineralogical Monitoring for the Mining and Minerals Industry” (König and Pöllmann, 2022).

The issue bundles up 9 scientific papers dealing with mineralogical monitoring using XRD. The different contributions focus on green metals such as lithium, nickel, copper, aluminium or titanium. The paper on lithium was the last publication together with Herbert (König and Pöllmann, 2021).

After 2 years of collecting and reviewing the contributions the Special Issue was ready. We finalised the editorial only 1 day before Herbert passed away. The book is published in memorial of Herbert (figure 12).

HERBERT AS PERSON

Herbert was a great scientist, an excellent mentor and very good friend. Besides his comprehensive mineralogical knowledge, he had the ability to recognize and initiate important research problems that motivated myself and companies like Malvern Panalytical to work on new analytical solutions. Personally, even more importantly, Herbert shared his huge life experience during our travels around the world. He was passionate to support and promote young talents specially those who do not have the means to do so themselves (figure 13).

What I will miss are the countless weekly conversations and calls, long discussions and friendly advice. What remains are happy memories that no one can take away – memories of all the trips together to Brazil, South Africa, Romania and many other remote places in the world where we collected minerals together.

He leaves a huge gap and I will miss him!

REFERENCES

König, U. & Pöllmann, H. 2002. Brasilien. Aufschluß, 53, 1-5.

König, U. & Pöllmann, H. 2008. Fossilien der Santana-Fauna – ein Einblick in das Leben des Uratlantik vor 110 Millionen Jahren. Aufschluss, 59, 331 – 334.

König, U., Benea, M., Göske, J. & Pöllmann, H. 2001. Der Berg Magura Uroiului in Rumänien – Locus Typicus des Pseudobrookits -. Aufschluß, 52, 271-281.

König, U. 2007. Synthese, Charakterisierung und Eigenschaften manganhaltiger Layered Double Hydroxides (LDHs). Hallesches Jahrbuch für Geowissenschaften, Reihe B, Beiheft 24.

König, U.; Pöllmann, H. 2022. Value of Mineralogical Monitoring for the Mining and Minerals Industry. Minerals 2022, 12, 902. https://doi.org/10.3390/min12070902 ISBN 978-3-0365-4894-4

König, U., Pöllmann, H. & Angélica, R.S. 2002. O Refinamento de Rietveld como um método para o controle de qualidade de minérios de ferro. Rev. Esc. Minas, Ouro Preto, 55(2), 111-114.

König, U. 2000. Quantitative Phasenanalyse von Eisenerzen mittels Rietveld-Verfeinerung. Diplomarbeit. Halle. Unveröffentlicht. 140p.

König, U. & Pöllmann, H. 2000. Rietveld refinement as a method for quality examination of iron ores. In: Rammelmair et al. (eds) Applied Mineralogy in Research, Economy, Technology, Ecology and Culture. Vol.1, 359-362, Balkema, Rotterdam, ISBN 90 5809 163 5.

Motzet, H., König, U. & Pöllmann, H. 1997. Auflichtmikroskopische Untersuchungen an Portlandzementklinkern aus verschiedenen Betriebszuständen – Phasenquantifizierung und Gefügebetrachtung, Ibausil – Weimar, Tagungsbericht, Band 1, 779-789.

Pöllmann, H., Neubauer, J., König, U. & Motzet, H. 1997. Clinker Quality control using combined Methods. A study using microscopy and X-ray techniques – especially Rietveld method. Proc. of the 19th Int. Conf. on Cem. Microscopy, Cincinnati, Ohio, USA, 195-221.

Pöllmann, H.; König, U. Monitoring of Lithium Contents in Lithium Ores and Concentrate-Assessment Using X-ray Diffraction (XRD). Minerals 2021, 11, 1058. https://doi.org/10.3390/min11101058

Rietveld, H.M. 1969. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71, doi:10.1107/s0021889869006558.

Tallarico F.H.B., Figueiredo B.R., Groves D.I., Kositcin N., McNaughton N.J., Fletcher I.R., Rego J.L. 2005. Geology and Shrimp U-Pb geochronology of the Igarapé Bahia deposit, Carajás Copper-Gold belt, Brazil: an Archean (2.57 Ga) example of iron-oxide Cu-Au-(U-REE) mineralization. Econ. Geol., 100:7-28.