03 – XRD MINERALOGICAL CHARACTERIZATION OF MORTARS FROM THE SÃO PEDRO NOLASCO FORT IN BELÉM, PARÁ

Ano 07 (2020) – Número 01 Artigos

![]() 10.31419/ISSN.2594-942X.v72020i1a3RCCN

10.31419/ISSN.2594-942X.v72020i1a3RCCN

Roseane da Conceição Costa Norat a.*, Giulia Maia Motta b, Marcondes Lima da Costa c

ab LACORE/ITEC/Federal University of Pará (UFPA), R. Gaspar Viana, 125, Campina, Belém (Pará),

Brazil, roseanenorat@ufpa.br a

c Workgroup Mineralogy and Geochemistry (GMGA) and Geosciences Museum/IG/UFPA, R. Augusto Correa, 1, Guamá, Belém (Pará), Brazil, marcondeslc@gmail.com.

*Corresponding author

ABSTRACT

Mortars are important building materials used as bonding agents in masonry such as rocks and bricks. In Amazonian military fortifications, rock and mortar were commonly used, as can be seen in the ruins of the São Pedro Nolasco Fort in Belém (Pará), whose origins date back to 1665. Demolished in 1842, its base structures were rediscovery in 1989 and were later reincorporated into the landscape. Two samples mortars of this Fort are the object of this research, classified as ‘traditional’ and ‘reconstitution’ mortars. This paper aims to understand mortars application in the São Pedro Nolasco Fort, through the mineralogical characterization to support the ongoing investigations on the compatibility of restoration mortars in Amazonian fortresses. The results indicated that traditional mortar is composed of quartz, calcite, kaolinite and hematite and the reconstitution mortar present quartz, calcite, gypsum and portlandite. Calcite indicates the presence of shell fragments and limestone nodules, alongside partial calcination of the lime used for traditional mortar. Shell fragments came from sambaquis deposits, common in the region. Hematite reflect the occurrence of fragments of the ferruginized sandstones and lateritic iron crusts found in traditional mortar. Portlandite and gypsum confirm the presence of pozzolanic cement for a reconstitution mortar. Calcite may be from the cement composition or for the lime addition into the mortar for the compatibility with the old mortar. The X-Ray Diffraction (XRD) method proved appropriate in identifying the mortars composition and assessing their correlation with possible sources of raw materials, application period of mortars, as well as their compatibility.

Key-words: Calcite; Hematite; Kaolinite; Cement; Quartz; Building Materials.

INTRODUCTION

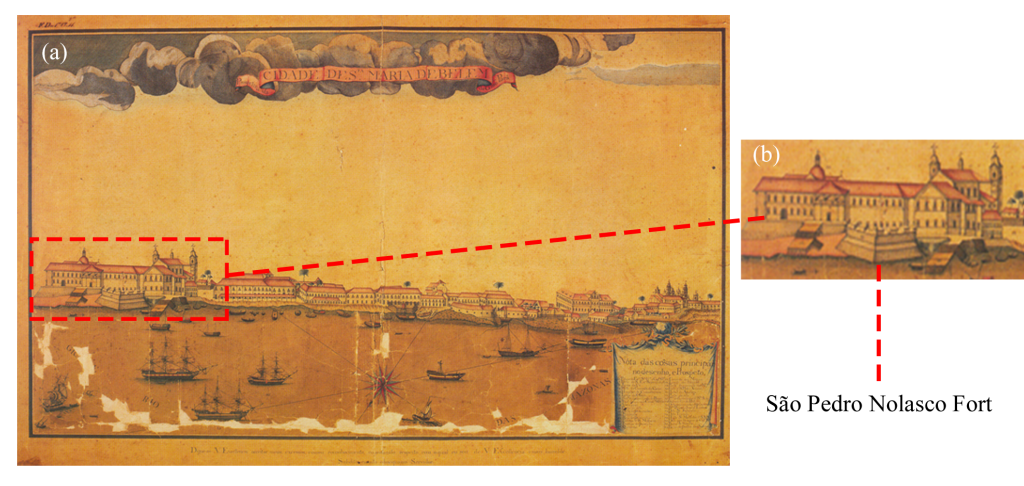

The construction of the São Pedro Nolasco Fort or Nossa Senhora das Mercês Bulwark in Belém (Pará) dates to 1665 and integrated a defense network that had other structures on land and in the Guajará Bay, protecting the old growth pole city represented by the occupation of religious missions, such as the Church and Convent of Mercedários (Figure 1).

Figure 1 – (a) Drawing prospects of the city of Belém (Pará) of the Ignácio Antônio da Silva; (b) and, in detail, the São Pedro Nolasco Fort. Source: Army Geographic Service, Rio de Janeiro. 1800 (Modified).

During the Cabanagem Revolt (1835-1840) the Fort was the center of many battles, which left it in state of ruin, leading to its subsequent demolition and grounding for the construction of a port area in 1842 (Souza 1885; Vianna 1905; Arruda 2007; Norat & Costa 2017; Norat & Costa 2018).

Only at the end of 20th century, its structures were rediscovered, and in 1989 its bases were identified after archaeological investigation and later it was inserted into the Estação das Docas Complex’s amphitheater (Arruda 2007; Norat & Costa 2017; Norat & Costa 2018).

The fortification’s strategic location aimed, beyond the expansion and protection of the area, the land’s morphological recognition. Initially, the historical documents refer that the provisional settlement was commonly done with the use of wood palisades or pau-a-pique. Then they progressed to robust constructions in stone masonry and mortared ceramic bricks (Souza 1885; Vianna 1905; Norat & Costa 2018).

The choice of rocky promontories with lateritic crusts in the banks of the Amazon’s rivers provided, in addition to a site with a strategic view, firm land and access to construction materials. Inputs from the site itself were commonly used, such as, rocks, sandy materials, silt and clay, the latter used in the production of ceramic bricks and mortars (Norat & Costa 2017; Norat & Costa 2018; Szlafsztein et al., 2018).

At this Fort, at least five types of mortars were identified, which indicate different insertion times, causing distinct behavior and visual characteristics. Aiming to obtain the lacking information about different mortars obtained in the interventions over time, two samples from the bases of the São Pedro Nolasco Fort (PN) were chosen as the objects of this research.

The aliquots are from a possible remaining original mortar from past structures (traditional) and the other from one from the interventions after its rediscovery (reconstitution) to support the identified materials’ compatibility. Thus, this paper aims to understand mortars application in the São Pedro Nolasco Fort through the mineralogical characterization to support the ongoing investigations on the compatibility of restoration mortars in Amazonian fortresses.

This study integrates a set of other research on the fortifications of the Amazon, due to its characteristics and construction materials in tropical weather conditions (Norat & Costa 2017; Norat & Costa 2018; Szlafsztein et al., 2018; Norat & Costa 2019).

MATERIALS AND ANALYTICAL METHODS

Samples

Among the five samples collected on July 17, 2018 from the ruin bases of the São Pedro Nolasco Fort, two representing the binding mortars were selected: one original called ‘traditional’ (PN.A.03/18) and other recent denominated of ‘reconstitution’ (PN.A.05/18).

The two mortars were firstly mesoscopically described in searching for characteristics, which allowed to make a comparison with other historical mortars already studied in the region and elsewhere. On the other hand, the mineralogical constitution was made only by XRD, since it is a very fine material and partly already friable.

X-Ray Diffraction (XRD)

XRD analysis was applied for binder and aggregates, that is widely used for mineral characterization of the materials. The results obtained may assist identifying possible sources of raw materials, and by correlations in the application period, as well as their compatibility. The samples were previously pulverized and then analyzed by the powder method using a diffractometer model D2 PHASER, Bruker (LAMIGA/IG/UFPA) with double 2θ/θ scanning by a Cu tube (Kα1 = 1.54184Å) and run analysis from 5° and 75° 2 Ɵ in 3462 steps of 0.2 seconds each. The data was treated with PANalytical’s X’Pert High Score Plus software from Mineral Characterization and Technology Lab of Geosciences Institute (IG), Universidade Federal do Pará.

RESULTS AND DISCUSSION

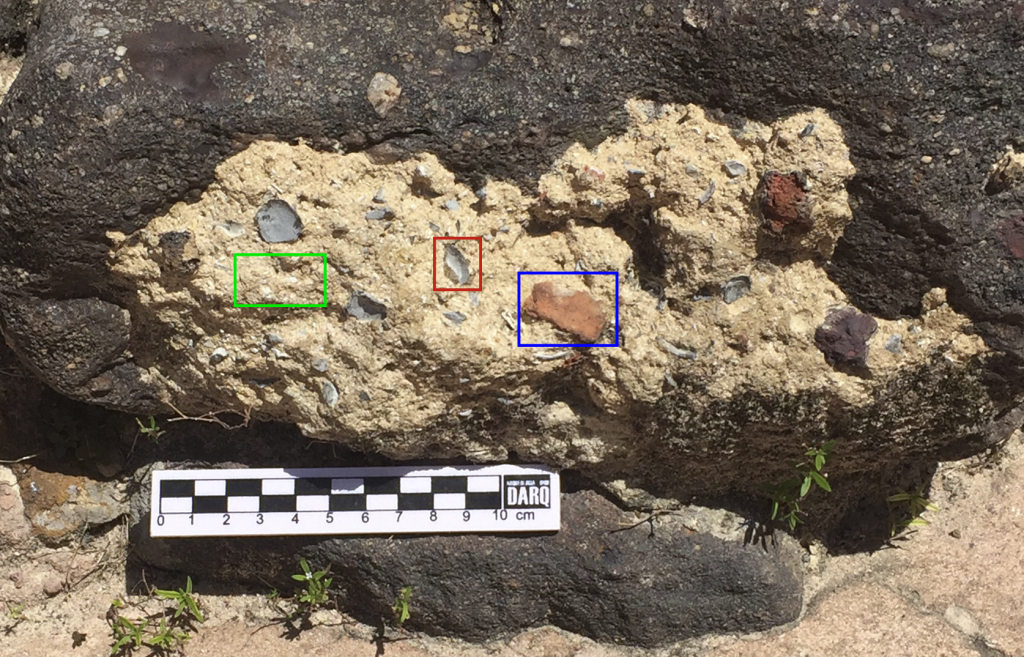

The sample PN.A.03/18 after mesoscopic analyzes can be classified as traditional mortar (Figure 2). It is inhomogeneous in aspect showed by changing grain size (clayey to sandy) and shade of yellow coloration. The coarse fraction is made of ferruginized sandstones, lateritic iron crusts and ceramics fragments, some white carbonate nodules and carbonate shells fragments. The presence of shell fragments suggests that they come from sambaquis deposits, which are very common in the Amazonian region. In general, it can be well correlated with other historical mortars from 17th through 19th centuries composed of fine and coarse rocks/minerals and shell aggregates and lime as binder (Loureiro et al., 2020).

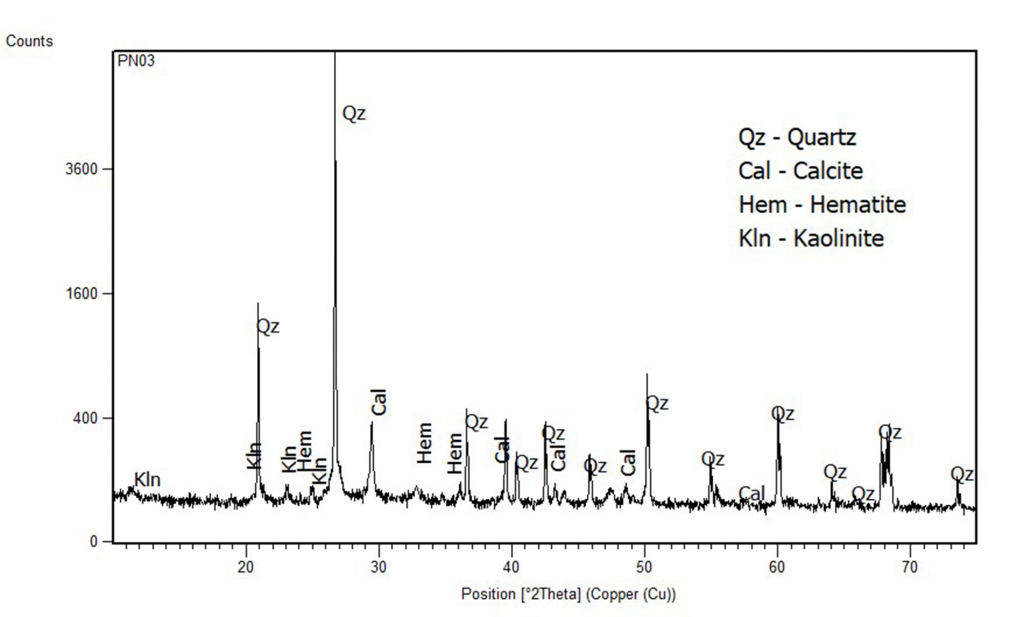

After the XRD analysis, this traditional mortar represented by sample PN.A.03/18 (Figure 3) is composed mainly by quartz (SiO2) and calcite (CaCO3), being hematite (Fe2O3) and kaolinite [Al2Si2O5(OH)4] accessory mineral phases.

Figure 2 – Mortar PN.A.03/18 found in the remaining bases of São Pedro Nolasco Fort. The green, red and blue rectangles highlight the white carbonate nodule, shell and ceramics fragment, respectively.

Figure 3 – X-ray diffraction (XRD) pattern of the traditional mortar (sample PN.A.03/18) showing its mineral composition made of quartz, calcite, hematite and kaolinite.

In contrast, the sample PN.A.05/18, with its light gray color and homogeneous appearance by mesoscopic analyzes, may be related to a more advanced technique, by using new industrial materials (Figure 4), and for this reason classified as reconstitution mortar.

Figure 4 – Mortar PN.A.05/18 found on the consolidated ground of São Pedro Nolasco Fort classified as nowadays reconstitution mortar.

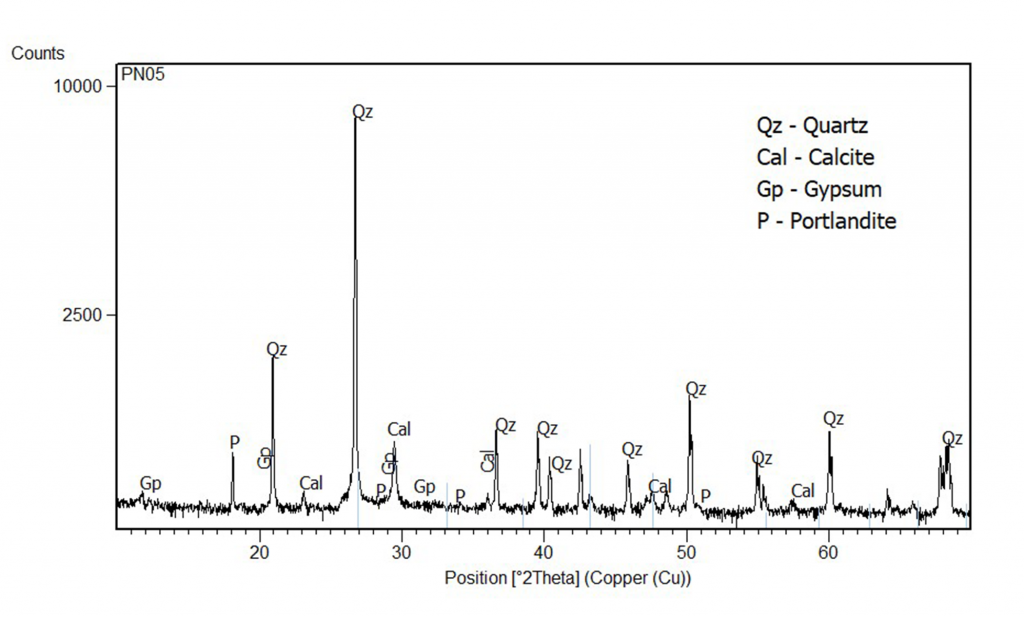

The XRD analysis (Figure 5) shows some contrast to previous traditional mortar, because in addition to the typical minerals, quartz and calcite, it presents portlandite [Ca(OH)2] and gypsum (CaSO4.2H2O). They are common mineral phases of industrial binder.

Figure 5 – X-ray diffraction (XRD) pattern of the reconstitution mortar (sample PN.A.05/18) showing its mineral constitution made of quartz, calcite, gypsum and portlandite.

The dominance of quartz in both mortar samples reflect the sand aggregate, which is a common procedure in preparing this material, while calcite can be part of the binder, as well as the mineral composition of white nodules and shells fragments, found typically in the traditional mortar. The presence of this mineral may indicate a partial calcination of shell fragments, even so the calcite nodules of limestones, during the production of lime (Santiago 2007; Norat 2017; Loureiro et al., 2020).

The presence of kaolinite in the traditional mortar may have been intentional in order to give greater malleability to it (Loureiro et al., 2020) or it may be impurities of the original sand material and rudimentary procedures, since clay mineral, like kaolinite, is always present in the surficial soil. To this ancient mortar, also called “bastard”, in addition to lime and sand, were added a clay soil and, occasionally, organic additives (Oliveira 2004; Norat 2017). Thus, the kaolinite came from the area surrounding the building.

Lastly, the hematite should be the main mineral phases of ferruginized sandstones and lateritic iron crusts, being responsible for brown to reddish color to these materials, as well as from kaolinite-bearing soils, supporting their yellow to brownish color.

Calcite in the reconstitution mortar (PN.A.05/18) may be from the Portland cement’s composition (Palomo et al., 2002). But, another possibility is the addition of lime in the mortar composition for the compatibility with the old mortar in the restoration process of the Fort.

However, gypsum and portlandite are minerals of pozzolanic cement (Baltar et al., 2008). Cement provides high elasticity, low permeability and a greyish color observable in the mortar, probably added in order to accelerate the setting of lime binder. It is not indicated for reconstitution of historic lime mortars, because it is physical, chemical and mechanical incompatibility to it (Palomo et al., 2002; Kanan 2008; Schueremans et al., 2011; Loureiro et al., 2020).

CONCLUSION

The analyzes of the mortars from the São Pedro Nolasco Fort allowed the identification of traditional and reconstitution mortars. The main minerals were both are quartz and calcite. Calcite indicates the presence of shell fragments and limestone nodules, along with partial calcination of the lime used in traditional mortar. Shell fragments came from sambaquis deposits, common in the region.

Portlandite and gypsum confirm the presence of pozzolanic cement for a reconstitution mortar. Hematite is not a mineral typical of mortars, however, of the ferruginized sandstones and lateritic iron crusts, common rocks of the region, found as fragments inside of the mortar.

Acknowledgments

The authors would like to thank PROPESP/UFPA for supporting scholarships (PIBIC/UFPA); to LAMIGA/IG/UFPA laboratories for analyzes and to the CNPQ for a financial grant (305015/2016-8) to the third author.

REFERENCES

Arruda E.S. 2007. Porto de Belém do Pará: origens, concessão e contemporaneidade. Rio de, p. 11-12.

Baltar C.A.M. Bastos F.D.F.; Luz A.B.D. 2008. Gipsita. In: Luz, A. B. (Ed.); Lins, F. A. F. (Ed). Rochas & minerais Industriais: usos e especificações. 2.Ed. Rio de Janeiro: CETEM/MCT, 990p.

Kanan M.I. 2008. Manual de conservação e intervenção em argamassas e revestimentos à base de cal. Brasília, DF: Iphan, Programa Monumenta. 172 p.

Loureiro A.M.S.; Paz S.P.A.; Veiga M.R.; Angélica R.S. et al. 2020. Investigation of historical mortars from Belém do Pará, Northern Brazil. Construction and Building Materials, v. 233, p. 117284.

Norat R.C.C. 2017. Materiais construtivos e sua biodeterioração em fortificações da Amazônia. Tese de Doutorado em Geologia e Geoquímica, Universidade Federal do Pará, Belém, 219 p.

Norat R.C.C.; Costa M.L. 2017. As Fortificações da Amazônia: desafios e perspectivas para sua preservação. In: Anais do Simpósio Científico 2017 do ICOMOS Brasil. 2017.

Norat R.; Costa M.L. 2018. As fortificações da Amazônia: novas fronteiras e desafios. Revista do Patrimônio Histórico e Artístico Nacional, v.1, p.125 – 143.

Norat R.C.C.; Costa M.L. 2019. Characterization, usage and provenance of building rocks in the Fortress of São José of Macapá (Amazon, Brazil). 19. Engineering Geology, 253: 214-228. https://doi.org/10.1016/j.enggeo.2019.03.022

Oliveira M.M. 2004. As fortificações portuguesas de Salvador quando Cabeça do Brasil. Salvador, Omar G.; Fundação Gregório de Mattos. v. 1. 264 p.

Palomo A.; Blanco-Varela M.T.; Martinez-Ramirez S.; Puertas F.; Fortes C. Historic mortars: characterization and durability: new tendencies for research. Eduardo Torroja Institute (CSIC), Madrid, 2002.

Schueremans L.; Cizer Ö.; Janssens E.; Serré G.; Van Balen K. Characterization of repair mortars for the assessment of their compatibility in restoration projects: Research and practice. Construction and Building Materials, v. 25, n. 12, p. 4338-4350, 2011.

Souza A. 1885. Fortificações no Brazil. Revista do Instituto Histórico, Geographico e Ethnographico do Brazil. Tomo XLVIII, Parte II, Rio de Janeiro, Typographia Universal de Laemmert & C.

Szlafsztein A.C.; Norat R.C.C. Costa M.L. 2018. O Forte São Pedro Nolasco ou Baluarte Nossa Senhora das Mercês em Belém do Pará: uma história em blocos de rochas. BOMGEAM- Boletim do Museu de Geociências da Amazônia, v. 5, n. 2.

Vianna A. 1905. As Fortificações da Amazônia. In: Vianna A. (ed.). Annaes da Bibliotheca Archivo Público do Pará. Belém, Typ. e Encadernação do Instituto Lauro Sodré, Tomo Quatro, p. 227-29.